01

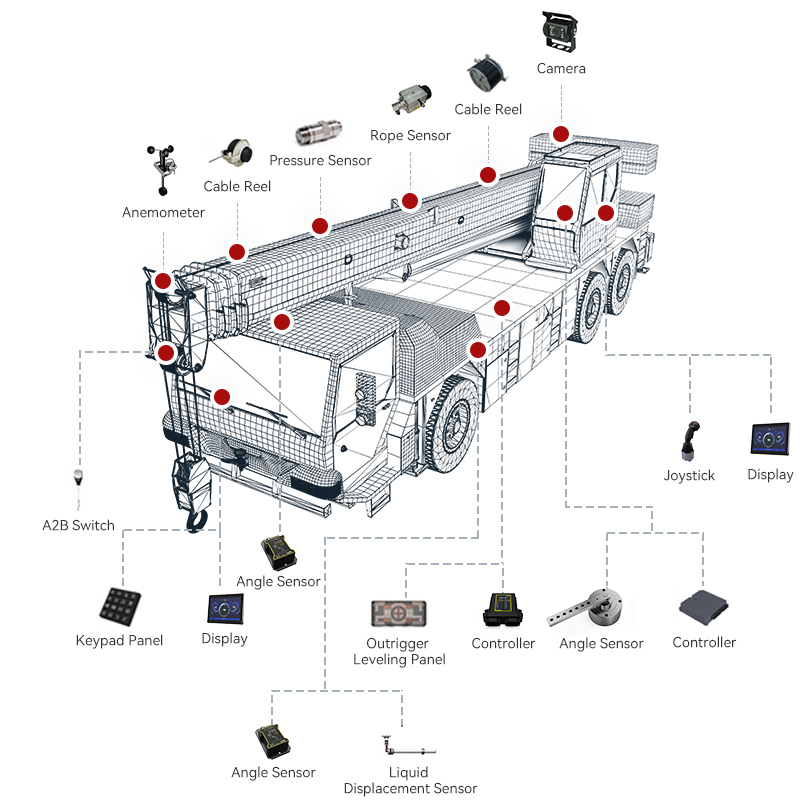

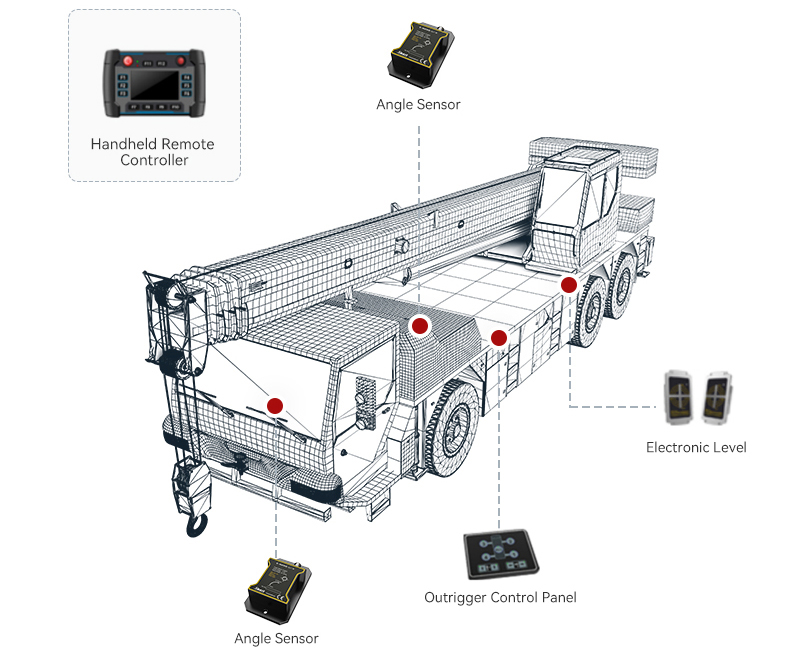

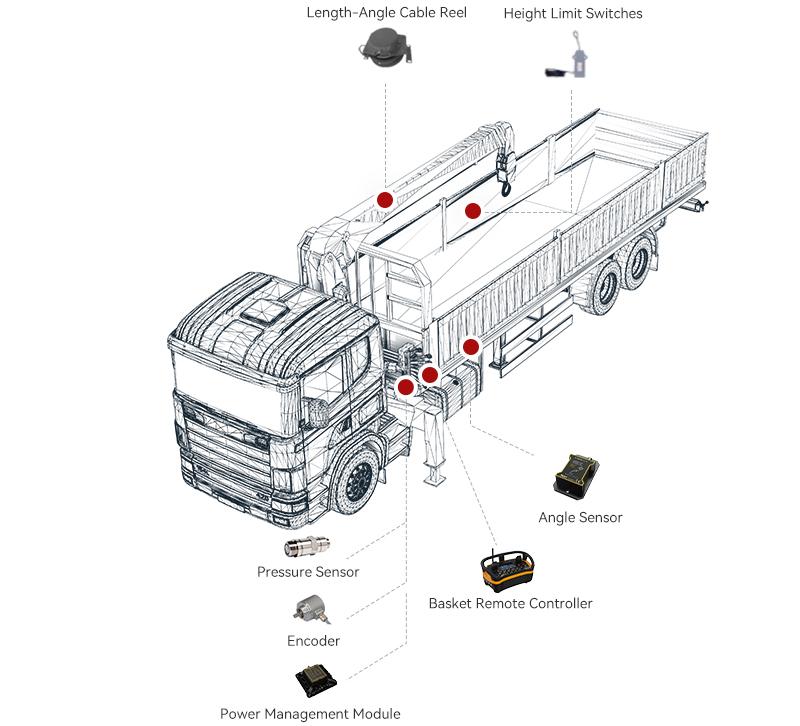

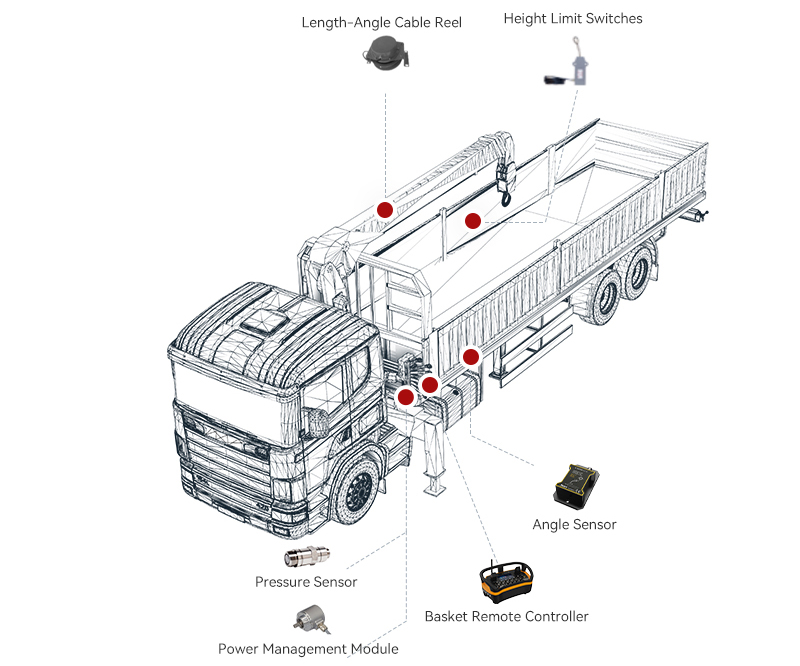

Full compatibility

Adapted to various types of tower cranes, greatly improving construction efficiency.

02

Intelligent security monitoring

Real time analysis of tower crane operation posture, precise warning of dangerous areas, and proactive risk prevention.

03

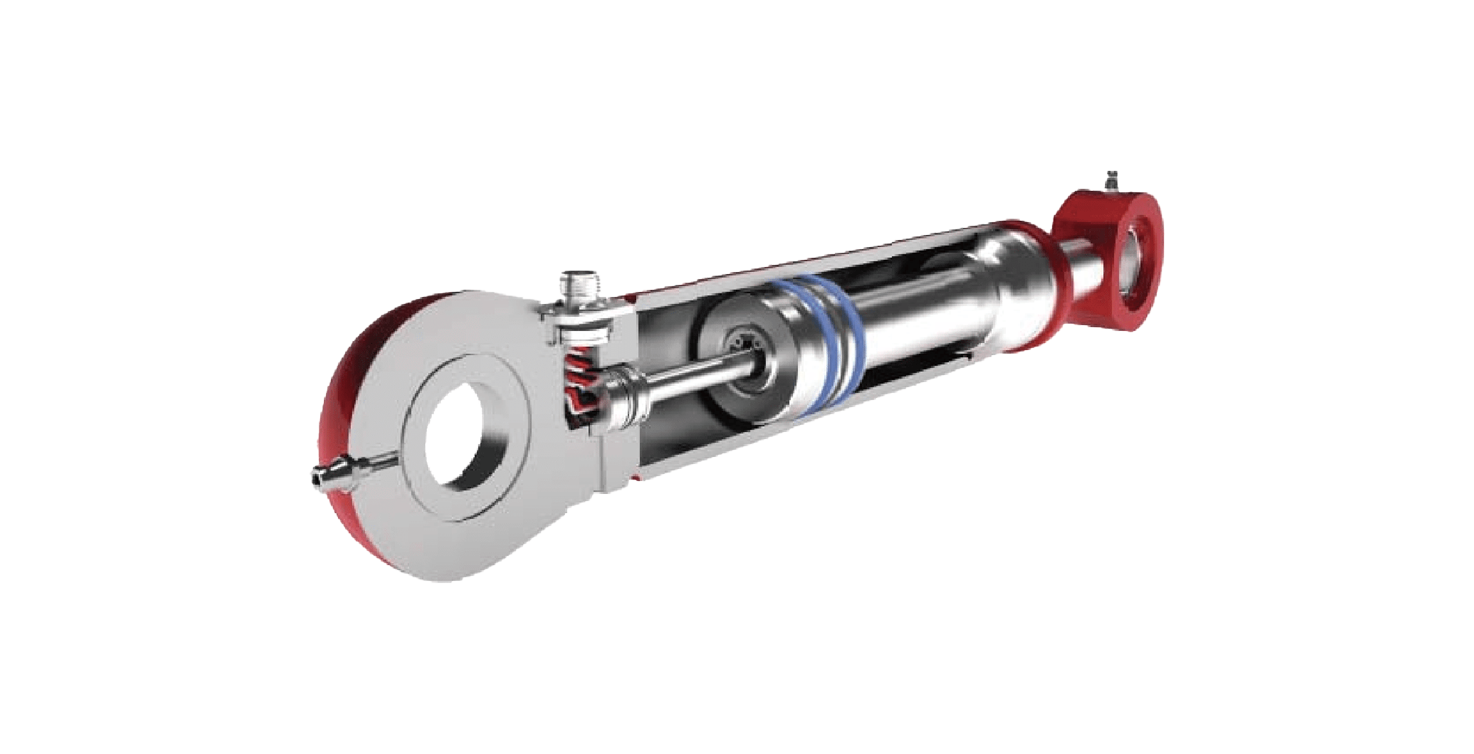

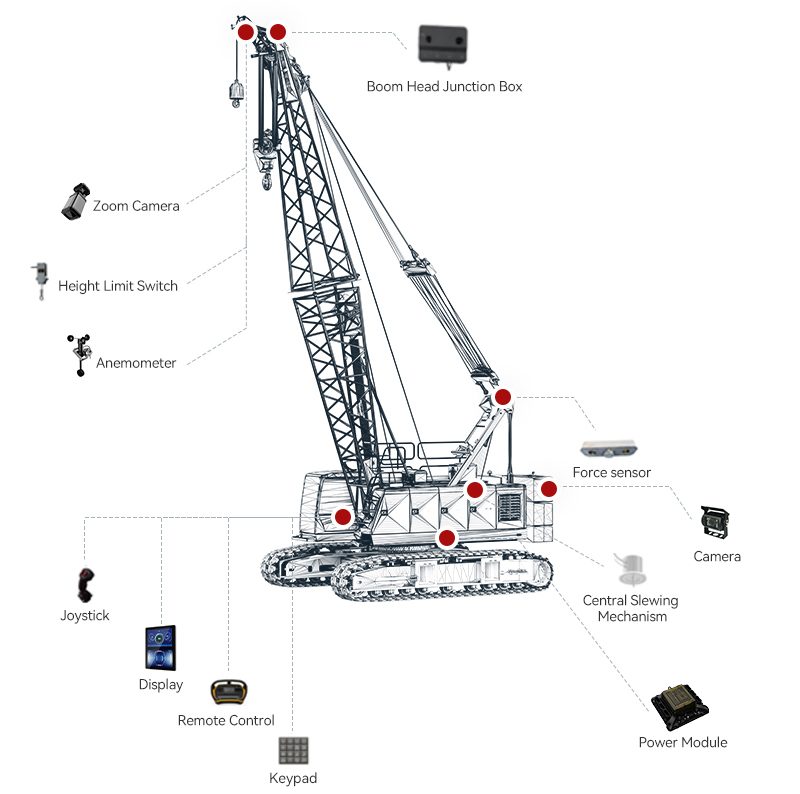

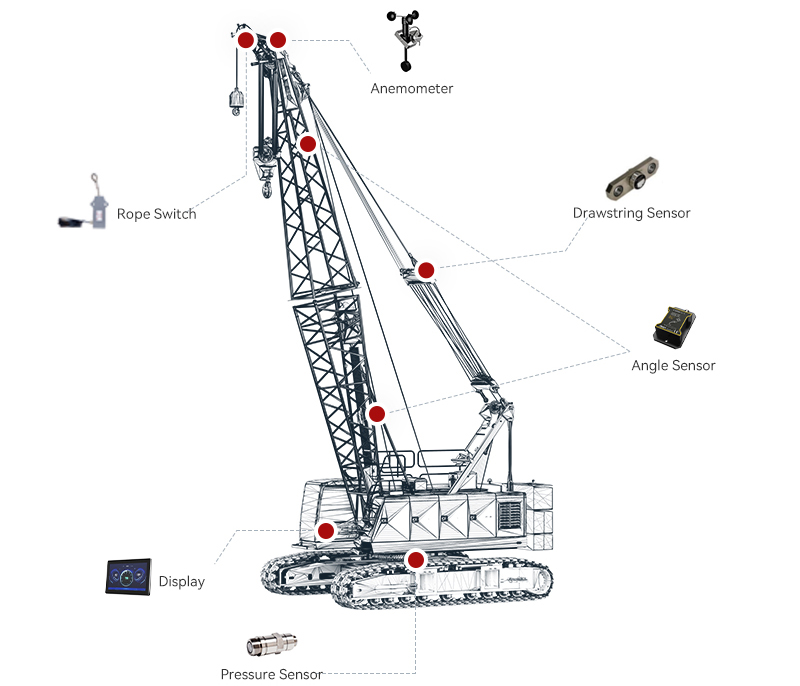

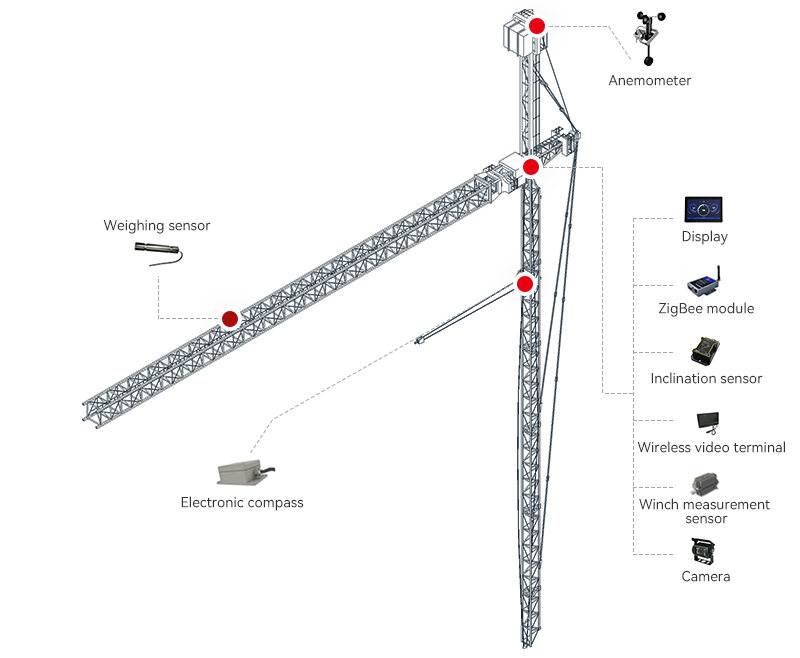

Safety Detection

Comprehensive monitoring of moment, wind speed, tilt angle, multi-dimensional to ensure construction safety.

04

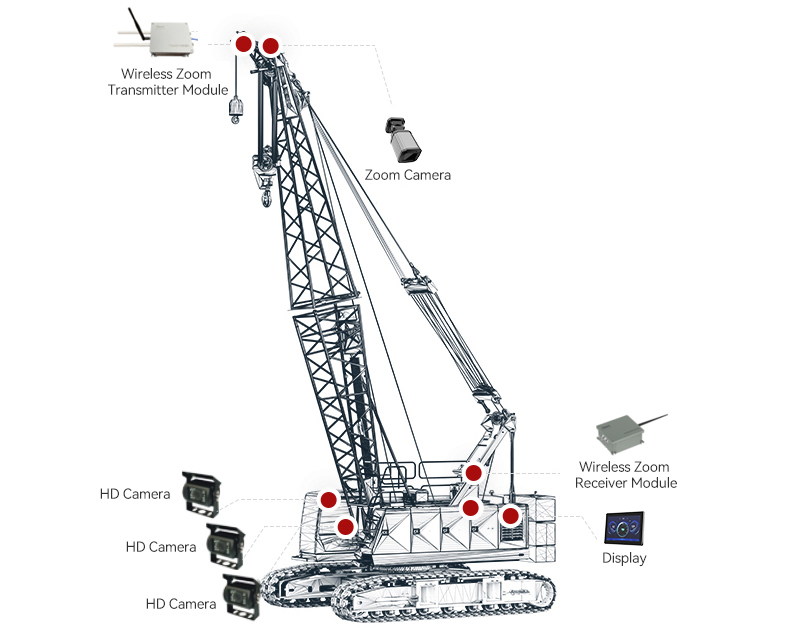

Real time multimedia transmission

supports multimedia information such as video and audio, real-time transmission, and improves on-site perception ability.

05

Data-driven decision-making

Record operation data throughout the process, provide operation status analysis at any time, and optimize decision-making support.

06

Intelligent data analysis

Quickly generate multiple data statistical reports, simplify supervision and management, and improve work efficiency.

07

Customized warning settings

support user customized warning parameters, fully adaptable to different site requirements.

08

Anti-collision technology

integrated anti-collision system to enhance operational safety.

09

Dual mode safety control

supports independent control of individual machines and networked control of tower cranes, adapting to different construction environments.